Basics of fiber optic closures and selection guide

What is a Fiber Optic Lock?

Fiber optic closure, also known as fiber optic splice sockets, is a device used to provide space and protection for fiber optic cables to be joined together. Fiber optic enclosure connects and stores optical fibers securely outside the facility or inside buildings. It can provide protection for fiber optic connector and fiber optic cables, as they have excellent mechanical strength and strong outer sheath, which ensures that the connectors will not be damaged by the hostile environment.

Types of optical fiber closures

Regardless of the size, type and configuration of your network, it is important to protect your connectivity. Depending on the different applications in the market, there are different types of fiber optic shields that users can choose from and help protect their networks.

Fiber-optic horizontal type closure

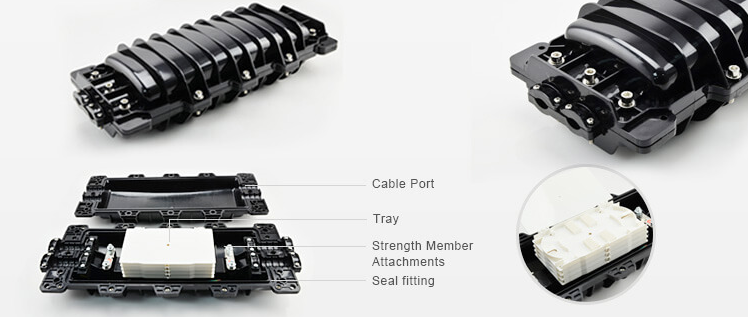

The horizontal fiber closure is like a flat or cylindrical housing. This type of fiber optic splice is most commonly used in antennas that are mounted or buried underground. Horizontal type fiber optic closure typically includes one or more fiber splice trays to provide space and protection for the fiber splices. Fiber splice trays used in different optical splices can have different designs and number of fibers. The typical number of fibers in the flat fiber weaves is 12 and 24 fibers.

The horizontal fiber optic splices are designed to be waterproof and dustproof. They are characterized by good adaptability and resistance to compression, as they are usually made of engineering plastic with high tensile strength. If fixed to a pole or suspended from cabling, these fiber splice connectors must be firmly held in place to avoid damage from weather and wind.

The figure below shows the 96-fiber horizontal splice closure of the optical fiber. It has two input ports and two output ports providing space for 96 fiber optic splices. Inside the fiber optic splice shield there are four standard splice trays with 24 fibers stacked together.

The vertical fiber closure looks like a dome, so it is also called dome closure for fiber optic splices or dome closure. The dome shape makes it easy to bury it in many applications, though it can also be used on the surface.

Due to the growing demands of the network, a wide range of models and configurations of vertical splices for fiber optic splices are available. High-capacity versions and weld tray count variants are also available on the market to meet the complex needs of today's fiber optic networks. The number of fiber optic closure dome inlet / outlet ports also varies depending on application needs. The closure of fiber optic dome splices requires high level sealing and waterproof technology due to its underground applications. Besides, in the case of underground closures, it is also important to keep insects and dirt away.

Shown below is a vertical type splice closure that has five entries that provide up to 24 fiber splices in two 12-fiber splice trays. In contrast, the inner fiber splice tray here is suitable for the vertical closure structure of the fiber splices.

Factors to consider when choosing a fiber optic closure

The optical network structure is often complex, especially the optical access part has unique requirements to function well. Reliable closure of fiber optic splices will eliminate many unnecessary problems. For example, in a network distribution system, a permanent, permanent optical closure can prevent a portion of the access link from being frequently inspected. And when the network reaches the distribution stage and drop lines, it will be great to close the weave, which allows more connections to be added. The following factors will help you choose the right fiber optic couplings and secure the fibers in your network.

1. Compatibility with cables

Good fiber optic closure is able to accept any fiber optic cable specified in the tender documentation. Therefore, it is important to establish cable compatibility before selecting the appropriate type of closure. The design of the fiber optic coupler changes with the areas of application. Therefore, the fiber optic antenna couplings will have a different design than that used for underground applications.

2. Number of cable ports

The cable port is also known as cable entry capacity. The number of ports in the fiber jacket reflects its ability to handle the number of cables. The cable entry capacity of a fiber optic coupler refers to the number of ports available for terminating the cable in the coupler. The number of ports supplied in the shutdown depends on factors such as network bandwidth and the number of cables used in the network. Typically, in order to reduce the physical size of high-capacity closures, smaller ports are used for manifold and drop cables.

3. Termination system

Before selecting a joint type, the cable termination system should be designed to ensure sufficient mechanical strength between the cable and the joint to ensure its lifetime operation. The materials used for the optical fiber couplings should also be able to minimize or eliminate the effects of the relative motion between the cable components, because the materials used in the optical fibers are easily subject to thermal expansion and contraction.

4. Types of welds

The splice trays in the fiber optic splice shield cannot accommodate enough cables if the cables are not connected properly. Typically ribbons or mechanical seals are larger in size, which can lead to a loss of capacity for the closure trays. Proper configuration of the splices avoids installation problems and improves efficiency. Therefore, when choosing a fastener for fiber optic splices, the types of splices should be taken into account.

5. Bonding and grounding

Proper connection and grounding of the conductive elements of the optical network must be ensured for the safe deployment and operation of the network.

6. Equipment and accessories

Depending on your network configuration, you may need to hang the fiber optic antenna from the communicator cable. Or they can be attached to the pole. In both cases, additional hardware is required along with the closures. Fixing and securing equipment or accessories should be able to withstand wear and tear as well as environmental loads.

7. Cable management

It is important to maintain a small bend radius in fiber optic cable installations. Ignoring this factor may affect link performance. When making your selection, consider a fiber optic closure that can handle cables well. And fittings that allow for easy installation can eliminate excessive stress or damage during handling.

Contact: Andy Huang

Phone: 0086-755-89239407

E-mail: sales@beskco.com

Add: No.3106,Longgang Avenue,Pidi Town, Longgang District, Shenzhen China

We chat